The previous online module included:

Experimental Aerodynamics

Delivered by Paula Garcia Ruiz

Understand how the wind tunnel works and the aero design process.

Find out about the different data sources available to aerodynamicists.

Discover more about wind tunnel model design size and the use of PIV.

Wind tunnel model and air flow

Delivered by James Eddison

James will cover wind tunnel model design, functionality and use.

As well as this, you will gain an understanding of air flow around the tyres and the correlation difficulties aerodynamicists face in this area.

Vortex flow and generation

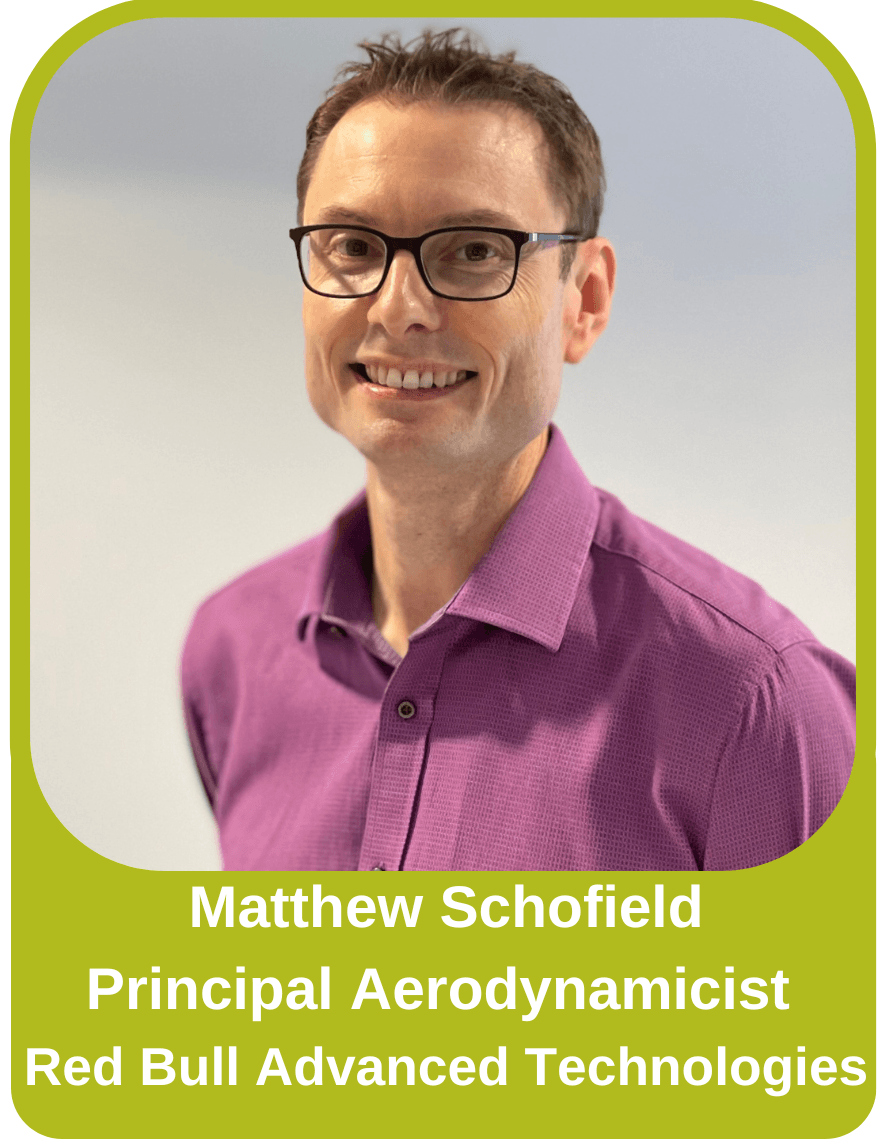

Delivered by Matthew Schofield

Discover how gurney flaps work and the pressure distribution effect.

Investigate vortex flow generation and why it is so relevant to F1 cars.

How vortices impact the aero maps of the car.

Plus Q&A sessions throughout the module!

Tutor details:

Paula Garcia Ruiz - Senior Aerodynamicist

Paula started her career as a Junior development Aerodynamicist at Williams Racing. Paula is now working as an Aero Science and Technology Aerodynamicist for Alpine F1 Team and works on developing new systems and technologies to enhance the performance of the Formula 1 car.

Matthew Schofield – Principal Aerodynamicist

Matt has 15 years of aerodynamic development experience, having worked for Alpha Tauri, McLaren and Sauber F1 teams through various changes of regulations in both aerodynamics and CFD. He is currently working for Red Bull Advanced Technologies on a broad range of projects.

James Eddison – Head of Aerodynamic Services

James has over 25 years’ experience in motorsport engineering. James started his aerodynamics career with Tyrrell working within a small design group. He then progressed through Jordan GP, Renault F1 through to Sauber where he works today as Head of Aerodynamic Services, which includes offering F1 aero development methods to customers, including wind tunnel testing.

The 15 June 2024 module covered:

Aerodynamic Theory

Delivered by Paula Garcia Ruiz

Understand how air molecules behave and interact with each other to generate downforce and drag.

Learn about Reynolds number, Bernoulli principle, Strouhal number, Brownian motion and boundary layers.

Trackside aerodynamics and the future of F1 Aerodynamics

Delivered by Dominic Harlow

Understand the elements of aerodynamic performance trackside in F1.

Explore how the future 2026 regulation changes will impact F1 aerodynamics and what you need to be aware of as an engineer.

Aerodynamic measurements in Formula 1: from sensors to models

Delivered by Marco D'Isanto

Master how pitot tubes, pressure scanners, kiel probes and pressure rakes work. You will also gain insight into how the sensors are used on aerodynamic models

Testimonials

"Really engaging and enjoyable. The F1 specific content put the principles into context and everyone who answered questions were very knowledgeable. The large chunk of Q&A was very useful and I'm glad a lot of time was dedicated to it. Thanks!"

"Thank you everyone, it was a really interesting module that allowed me to learn more about F1 aerodynamics, through technical information and practical examples that I couldn't have found anywhere else."

"As a fan of F1 and an engineer working in the automotive industry, I found this module absolutely valuable as it creates an opportunity to meet with professionals in the sport and ultimately bridges the gap for people outside the F1 bubble. It has really fuelled my interest for looking at an opportunity in motorsports. Looking forward to the next modules!"

On successful completion of the Online Module, graduates are awarded an industry recognised certificate of completion from the MIA. The online modules will take place on 15 June and 13 July, via Zoom and the MIA Campus platform. The cost for this industry recognised learning opportunity is just £295*, per module. This price includes exclusive technical material, the opportunity to put forward questions to the tutors, access to the webinar recording and a certificate of attendance.

*Bundle packages are available if you enroll on multiple modules and there is a special loyalty offer for MIA Members and past participants. Contact elinor.morris@the-mia.com for more information.

How teams use F1 aerodynamics to win

Today’s Formula 1 cars are some of the fastest in F1’s history. In 2020, Lewis Hamilton set the record for the fastest average speed 264.36km/h (164.27mph) during a lap in Monza. Although previous cars have reached higher top speeds, Hamilton’s record highlights the impressive cornering speeds of modern F1 cars.

Why is downforce important?

To maximise speed in the corners, you need to increase tyre grip. In F1, the majority of this grip comes from the downforce generated by the aerodynamics package. This load forces the tyre into the track’s surface, increasing the tyre’s contact patch and available grip.

Without downforce, F1 cars only have enough grip to corner at lateral accelerations of around 1.5G. Whereas, a high downforce set-up can achieve up to five times more at 7G. This allows drivers to push much harder in the corners, resulting in much higher cornering speeds. It’s this hunt for downforce that has led to large wings, complex underfloors and intricate winglets.

What about drag?

Unfortunately, the first rule in aerodynamics is an increase in downforce leads to an increase in drag. It’s the job of the F1 aerodynamicist to design legal parts that extract downforce yet minimise drag.

The drag vs downforce trade-off is a key part of base car design and the set-up compromises on race weekends. The relationship between the two is usually referred to as efficiency or the lift to drag ratio (L/D). Lift in this case is a negative value representing downforce. More downforce increases cornering speed, but the accompanying increase in drag decreases straight-line speed.

Each track has a different efficiency requirement based on the corner types and the amount of straight line running. The break-even efficiency is the point at which adding more downforce doesn’t give you a faster lap time. The time gained from more downforce is exactly the same as that lost through a lower top speed on the straights. Monza demands a high L/D car configuration, achieved by sacrificing downforce to reduce drag. Monaco’s L/D requirement is very low so car set-up is all about downforce.

Aerodynamic development

To optimise aerodynamic performance, teams run wind tunnel programmes and CFD studies alongside track testing. However, to control costs, the Aerodynamic Testing Restrictions (ATR) limit the amount of wind tunnel and CFD time a team can utilise in every eight-week period. For 2022, the lowest ranked team in the 2021 championship are allowed 320 wind tunnel runs and 6.0 Mega Allocation Unit Hours (MAUh) of CFD. Find out the latest ATR limits in Article 9.3 of the FIA Sporting Regulations.

The power of CFD

CFD is fundamentally a mathematical model based on the Navier stokes equations. The internal and external aerodynamics of a detailed 3D CAD model can be simulated without the requirement for physical parts. This can save time and a lot of money for teams when compared to the infrastructure and manufacturing needs of a wind tunnel programme.

As processing power and the modelling of complex phenomena such as turbulence and vorticity has improved, the importance of CFD has increased. One of the biggest benefits is the ability to interrogate flow fields in much greater detail then with physical testing. This has been a game-changer for the complex aerodynamics of F1 cars.

Wind tunnels in F1

CFD is the tool of the future, but is still not capable of running enough configurations or test points in a sensible timeframe. Until the processing power exists, wind tunnels remain the key tool for developing aerodynamic performance.

Closed-loop F1 wind tunnels provide carefully controlled air flow speed, humidity and pressure to allow very precise drag and downforce measurements to be made. Teams run complex 60% scale models through a range of ride height, yaw, steer and roll attitudes to compare development parts. Runs are carefully planned and run to maximise the amount of work that can be done under the requirements of the ATR.

Interested? Click the buttons below to register!

Media Partners